Food Service Distributor Case Study

Food Service Distributor Case Study

One client of OMNI Systems is a national distributor of food products and services. They provide food and drink, menu planning, inventory programs, software and many more products and services to restaurants, hospitals, hotels and various other businesses. The company operates 32 locations around the country.

$0

0

0

The Challenge

Labels are an important part of the client’s business. Products are stored on racks in warehouse facilities, and each item on the rack has a label called a “pick sticker.” In addition, each rack has a label called a “rack sticker” that lists all of the items on the rack. Workers, called “pickers,” process each order by retrieving items from the racks, and stacking them onto pallets.

Once the pallets are built, they are loaded onto trucks. When the driver delivers the pallet, he uses a scanner to scan the pick stickers to ensure delivery of the correct items.

The company needs a lot of labels, and needs them quickly. They require labels that are printed clearly and cleanly so they can be easily scanned by pickers and drivers. These labels must have dependable adhesive backing so they don’t fall off of racks or products.

Since they require a large number of labels, the labels need to be produced in a cost-efficient manner. The labels themselves must be reasonably priced and must not cause undue wear-and-tear on the printheads used to create them.

This company has facilities all over the country that need to coordinate with each other, so labeling practices must be consistent across all facilities. This means that one label provider must be able to service all 32 locations at the same time.

The business systems administrator at the primary locations of this company was dissatisfied with the labels and service the company was receiving from their previous label vendor. The labels themselves were of inferior quality, frequently fragmented or tore, or were unable to be scanned.

The printheads used to print these labels didn’t last long. The heads burned through frequently and had to be replaced. Printheads are one of the more expensive components of creating labels, so it is important that they last as long as possible—with labels that don’t cause accelerated wear.

The Solution

The company approached OMNI Systems to discover a better solution for their labeling needs. OMNI worked with the business systems administrator to set up a test at her division, with an OMNI representative working on-site at the primary facility. They performed extensive testing for the products and capabilities, so that OMNI could create a customized solution that met the client’s specific needs. The business systems administrator was able to sample the new products to determine which was best for her operations.

The new program includes several elements, including:

1. All-White vs. Color

The company previously used a color-coded labeling system to indicate pallet location, truck and route assignments and delivery dates. These colored labels were more expensive than white labels, shortened the lifespan of the printheads and reduced the legibility and scannability of each label.

Now the company uses all-white labels, which are less costly to produce. White labels have also reduced wear on the machines—while making the production process faster. There have been no organizational issues from discontinuing the color labels.

2. Top-Coated Labels

The new labels the company uses have a top coating. This is an improvement over previous labels; they print faster, but are just as clear. They enable perfect scanning. Printing them creates less friction and wear on the printheads, meaning they last longer. The printheads also don’t fragment the stickers as easily as before. These labels are reliably legible.

The labels the company uses are OMNI direct thermal labels. The labels are specifically developed for use in the food service sector.

3. New Cleaning Procedures

The printheads required to create direct thermal labels are expensive. It is important to the company to extend the life of the printheads as long as possible. The business systems administrator worked with OMNI Systems to investigate methods of extending the life of printheads.

The business systems administrator found that increasing the frequency of cleaning the heads helps the printheads last longer, and keeps the sticker quality consistently high. She initiated a protocol of cleaning the heads prior to each use, and clearly directed her team to adhere to the scheduled cleanings.

The Results

The new labels have been an excellent solution for OMNI’s client, and they are very gratified. At the primary facility alone, more than $1,000 per month has been shaved off the budget. Naturally, the executives of the company are pleased.

Money is saved by using white, top-coated labels. Money is also saved by extending the service life of the printheads used to create the labels. The new cleaning protocol—and using the 99.5% alcohol wipes—helps contribute to the longevity of the printheads.

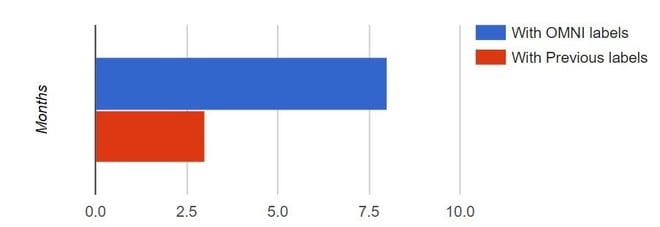

With previous labels, printheads lasted approximately three months. Using OMNI labels, printheads last more than eight months!

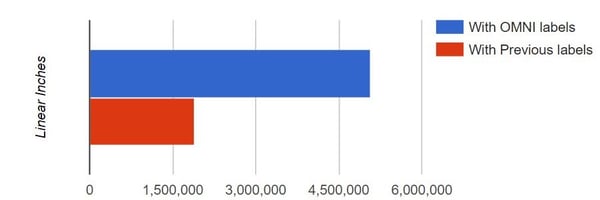

With the company’s previous label supplier, printheads lasted for 212 hours, just long enough to produce 79,524 inches of labels. Now, using OMNI labels, printheads can last for 5,884 hours and produce 449,424 inches of labels.

The company is appreciative of the excellent customer service they have received. OMNI’s client says they would absolutely refer OMNI Systems to other companies.

The business systems administrator states, “Any label company can provide labels. But if a problem arises, who responds, and what is the response? How quickly are the problems solved? With OMNI, the response is immediate. An OMNI representative will come to your facility, review your production process to discover what causes the issue, and will correct it. OMNI’s service is impeccable!”

How Can We Help?

Are you looking for a supplier of thermal labels, thermal transfer ribbons, water-activated tape and other thermal label products? Please fill out the form below. An OMNI Systems representative will contact you to discuss your needs.

Founded in 1990, with headquarters in Cleveland, Ohio, OMNI Systems is the largest, privately owned label converter in the U.S.

Get A Quote

©2024 OMNI Systems LLC. All Rights Reserved.